HPP TECHNOLOGY

Pascalisation and its advantages.

An experienced process in process of democratization

Pascalisation or the HP Processing (HPP) is used to improve the preservation of fresh foods.

Contrary to the traditional processes of preservation in the food-processing industry, the pascalisation do not use a thermal system. It offers to heat sensitive products an interesting alternative compared to the classic heat treatments.

Pascalisation: how does it work ?

The pascalisation (HPP) consists in applying high pressures to fresh foods or drinks in order to stabilize them and increase their shelf life.

This technique created in the 1990s, modifies the structure of molecules and reduces the population of microorganisms.

The pascalisation can also be called cold pasteurization or high pressure processing (HPP).

Advantage of the pascalisation of food and fruit juice

This cold treatment allows micronutriments and aromas not to be degraded.

This technique is particularly relevant in the production of high added value products (thanks to the preservation of the gustative and nutritional qualities). The pascalisation is used on fruit juices, meats, fishes, milk …

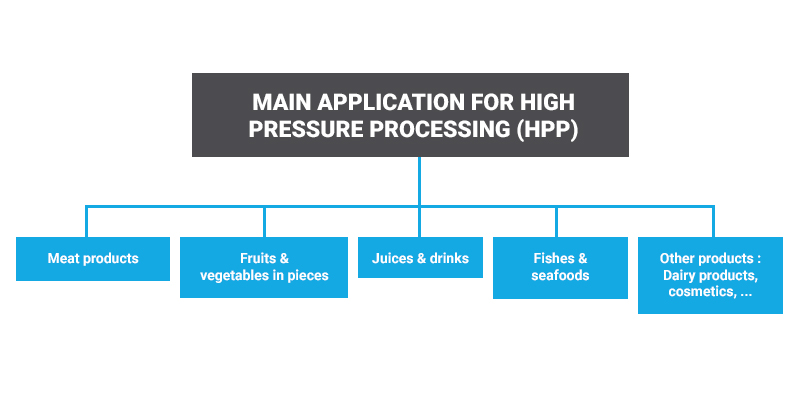

Applications of hpp technology

The applications of Pascalisation, or high-pressure processing (HPP), in the food industry.

This Technology is used for the meat-based products meat and delicatessen, fruits and vegetables in pieces or puree, juices and drinks, seafoods and fishes, as well as some dairy products

]]>Q: Are there any organizations in the food industry that have forums for mechanics to get together and discuss food plant challenges?

A: This is a great idea and one that would advance segments of the food industry. I would like to substitute the word technician for mechanic as there are many technical folks (instrumentation technicians, electrical technicians and operating engineers) that may not be mechanics, but their jobs are crucial to the company’s success.

I know of no organization that offers this forum, short of discipline-specific unions and professional associations (e.g., IBEW, Operating Engineers). The reasons are many.

Within the food industry, there are very different types of products and processes. They range from liquids to colloids, pastes, breads, meats and vegetables. There also is a myriad of packaging required. Additional sub-groups exist within these major groups. For example, under liquids may be soda, probiotics, beer, wine, bottled water and juices, each with unique manufacturing requirements.

Looking at this from another vantage point, there are some technicians whose competency lie in the areas of process, electrical, utilities, controls, packaging, lubrication and others. Their primary learning concerns are within the areas they are responsible for.

Beverages, meats and dairy are examples of specific food channels. Each has its own associations. The International Dairy Foods Association, American Beverage Association and the American Meat Institute are examples. You may want to contact the anchor association in your specific area to see if there are forums that are offered.Submit your question on our Plant Maintenance page.

Another alternative may be having “Lunch and Learn” sessions. These are conducted by vendors as a service. They are brief and informative and technicians love them.

As a last resort, maybe to try to develop your own forums with local companies that have technicians with similar competencies producing noncompeting products. This would be a lot of work in the short run, but could have a great impact long term.

]]>